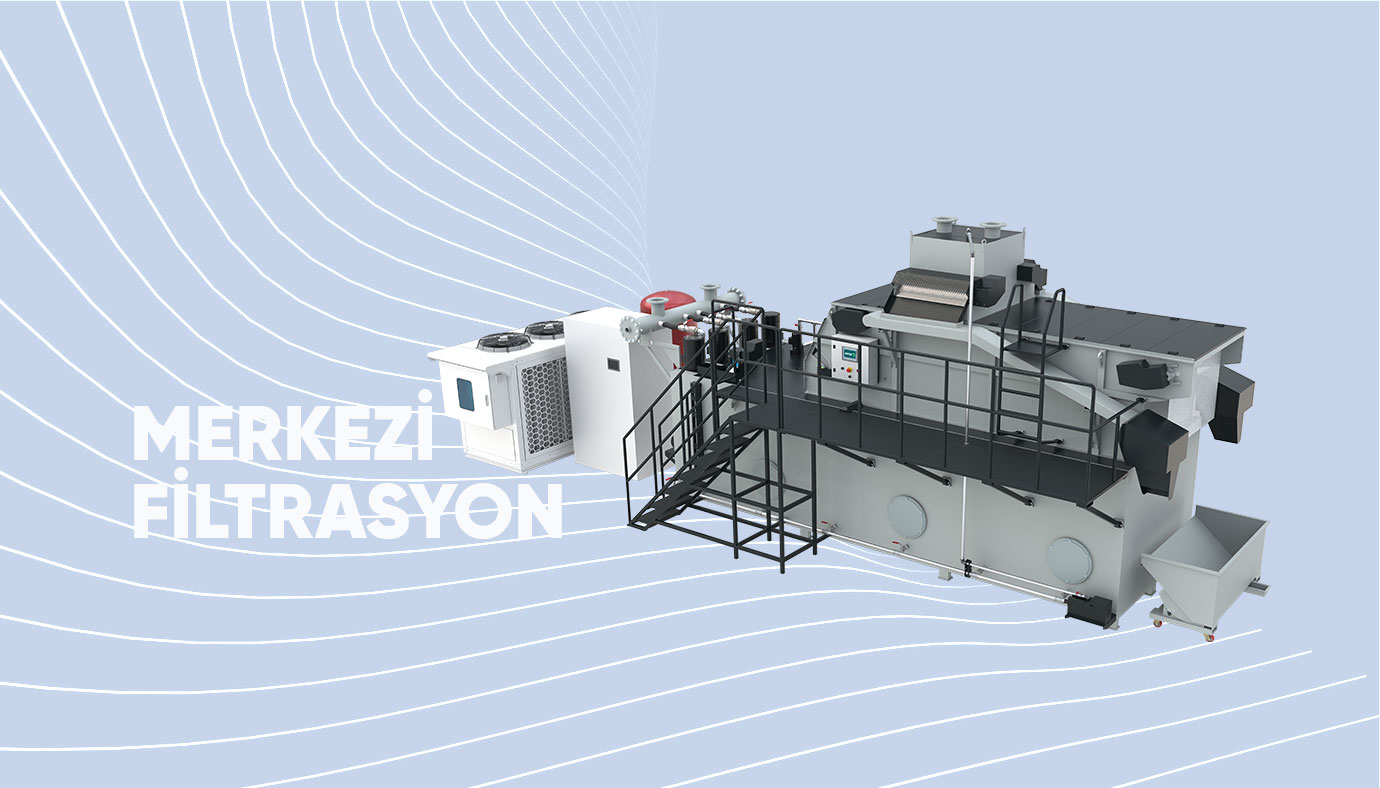

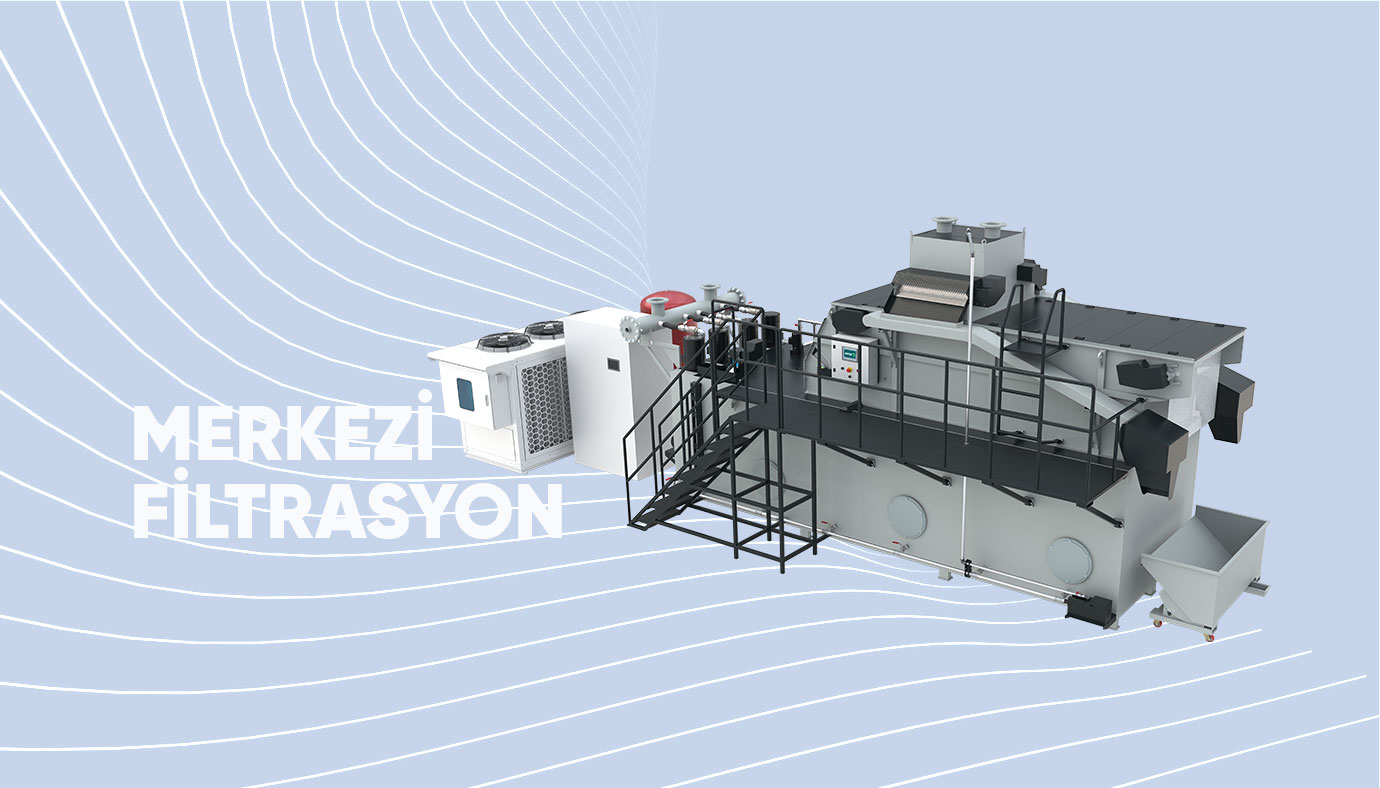

Make your production processes cleaner, safer, and more efficient with Central Filtration Systems developed for CNC machines and machine tools. Thanks to high-performance filtration, reduce fluid consumption, extend tool life, and lower your operating costs. Enhance your production with the quality of Astor!

Central Filtration Systems that provide continuously clean fluid enable you to achieve maximum performance in production. Discover the advantages of reduced maintenance, lower costs, and sustainable manufacturing!

These are industrial systems that collect contaminated coolant fluids in a central unit, filter them, and recycle them for reuse. Central filtration provides continuously clean fluid throughout production processes, reduces costs, and extends the service life of your machines.

Filtration Efficiency

Successful Implementation

Coolant Supply

Filtrasyon Performansı

Hassas Filtreleme

Yağ Ayrıştırma Kapasitesi

Kesintisiz Sıvı Beslemesi

Kolay Kullanım

Milling and turning operations

High-precision machining processes

Automotive parts manufacturing

Aerospace and Defense Industry

Ensures maximum production efficiency by continuously cleaning fluids with precision filtration technology.

Designed for long-term use, significantly reducing maintenance costs and machine downtime.

Operates reliably for many years thanks to its durable and high-quality components.

Designed for Chip Separation and Coolant Filtration

* Collects and filters coolant from multiple CNC machines in a centralized system.

* Provides high-capacity filtration ideal for large-scale production facilities.

* Easily integrates into various production lines and extensive manufacturing areas.

* Energy-efficient design helps reduce operational costs.

* Self-cleaning function ensures continuous and uninterrupted filtration.

* Durable construction and automatic purification system enable long-term use with minimal maintenance.

* Coolant reuse reduces environmental waste and operating expenses.

* User-friendly design allows for fast and easy maintenance.

Coolant Preservation with Holiday Mode

During planned production stops such as holidays or scheduled maintenance, the system automatically circulates the coolant to prevent degradation and bacterial growth.

Uninterrupted Performance Thanks to its high-durability components, the system operates with consistent efficiency and reliability for many years.

Eco-Friendly and Cost-Effective Reduces waste coolant to protect the environment while lowering your fluid consumption costs.

Discover how central filtration systems enhance quality and efficiency in CNC manufacturing and the value they add to your production

Discover the 5 essential benefits of central filtration systems in CNC production. Here’s why you should switch — for efficiency,

Making the right decisions when investing in a central filtration system ensures long-term gains. From needs analysis to automation, filtration