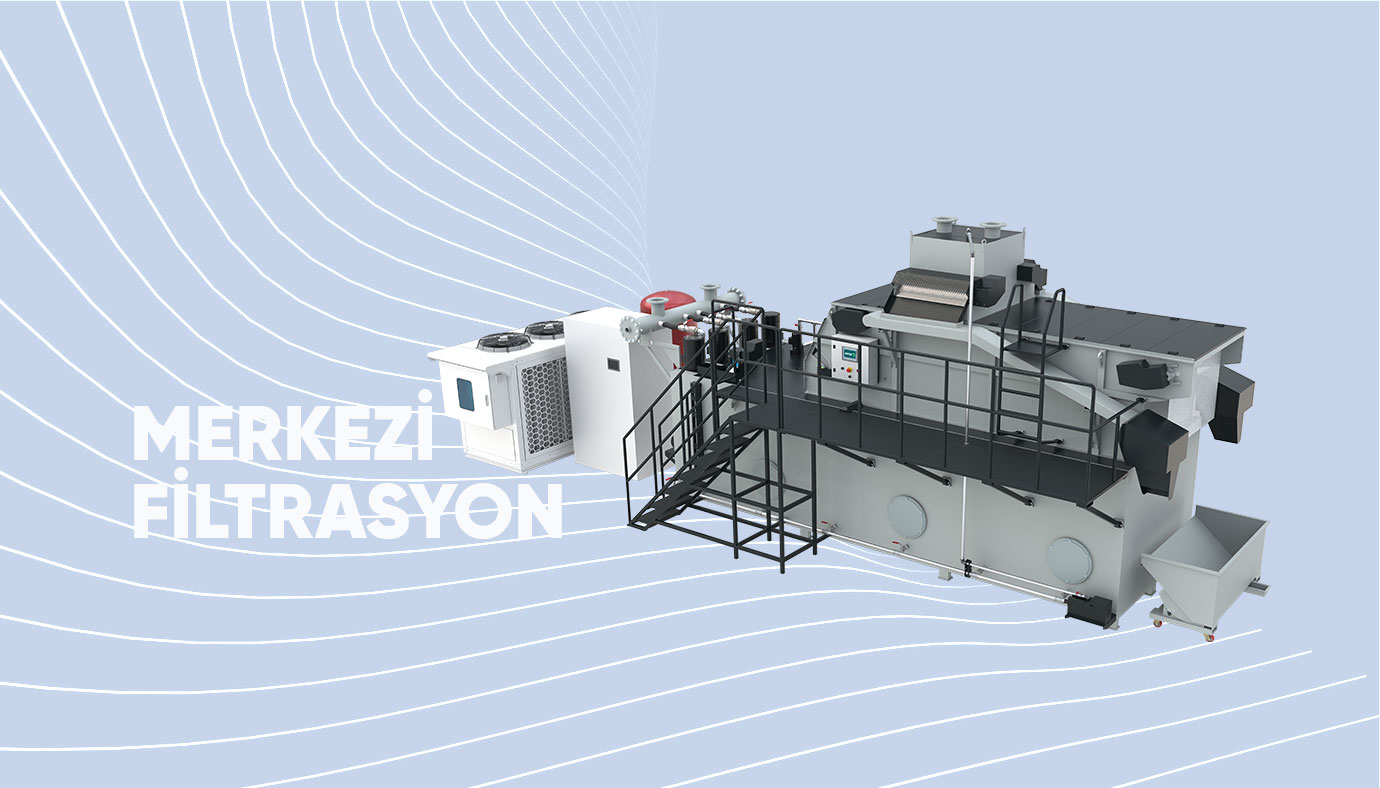

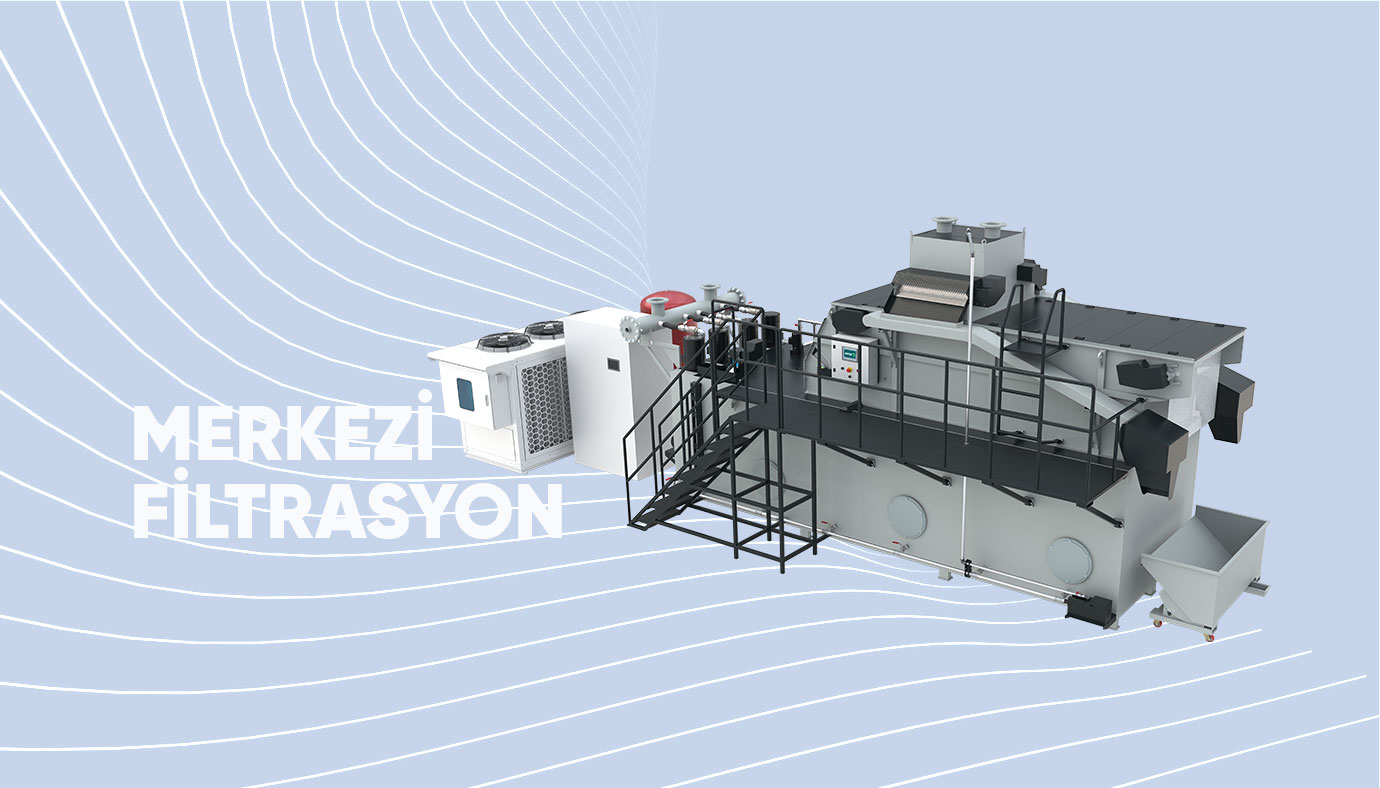

Discover how central filtration systems enhance quality and efficiency in CNC manufacturing and the value they add to your production process. CNC machines are a cornerstone of modern industrial manufacturing, providing high-precision results. However, for these machines to operate efficiently and have a long service life, the cleanliness of the coolant used is of critical importance. This is exactly where central filtration systems come into play—offering one of the most effective solutions to enhance both quality and efficiency in CNC production. In this article, we explore in detail how a central filtration system improves quality, boosts efficiency, and reduces production costs in CNC environments. What Is a Central Filtration System? A central filtration system collects and filters contaminated cutting and cooling fluids used in CNC machines from a central point. After filtration, the clean fluid is recirculated back into the production process. The system consists of: Collection Tanks: Gather dirty fluid from CNC machines. Filtration Unit: Removes chips and particles through micron-level filtration. Clean Fluid Tank: Stores the filtered liquid. Pump System: Delivers clean fluid back to the machines. How Central Filtration Improves CNC Quality 1. More Precise Production with Clean Coolant Dirty coolant can reduce surface quality and cause machining errors. A central system ensures constant clean coolant, resulting in smoother, more accurate cuts. 2. Extended Tool Life Contaminated fluid wears cutting tools faster. Clean coolant extends tool life and reduces the frequency of tool changes. 3. Better Surface Quality Filtered coolant helps achieve smoother surface finishes and higher-quality parts. 4. Consistent Production Standards Central filtration reduces quality fluctuations caused by contaminated fluid, ensuring stable and repeatable machining outcomes. How Central Filtration Enhances Production Efficiency 1. Reduced Downtime Clean fluid prevents clogging and breakdowns in CNC machines: Fewer malfunctions Continuous production flow Minimized unplanned maintenance stops 2. Easier Maintenance Centralized chip and particle collection simplifies machine cleaning and reduces manual effort. 3. Lower Coolant Consumption Coolants are constantly recycled, reducing fluid usage and cost. 4. Automated Operation Automation minimizes human error, ensuring smoother and more efficient production. Cost Advantages of Central Filtration Fewer Tool Changes → Lower tool costs Reduced Machine Cleaning → Lower maintenance labor Less Coolant Usage → Cost savings on fluids Minimized Repairs → Fewer breakdowns due to dirty coolant Energy Efficiency → Automated system lowers energy consumption What to Watch for in Central Filtration Systems Regular Maintenance: Inspect filters and pumps periodically. Sensor Monitoring: Calibrate automation sensors regularly. Fluid Quality Checks: Analyze clean fluid at intervals. Spare Parts Availability: Keep essential parts in stock (filters, pumps, sensors). Conclusion Central filtration systems significantly enhance CNC production by: Extending tool life Reducing maintenance needs Minimizing waste and environmental impact Increasing efficiency and product quality By implementing a central filtration system, you modernize your production line while reducing operational costs. 📞 +90 332 342 27 90👉 Learn more: https://astorkonveyor.com/urunler/merkezi-filtrasyon-sistemi/ #Filtration #CNCProduction #Efficiency #CentralFiltration #CoolantManagement #MaintenanceEase